One Excellent Job Leads To Another

TPS-59 Radar Power System Restoration

Project Overview

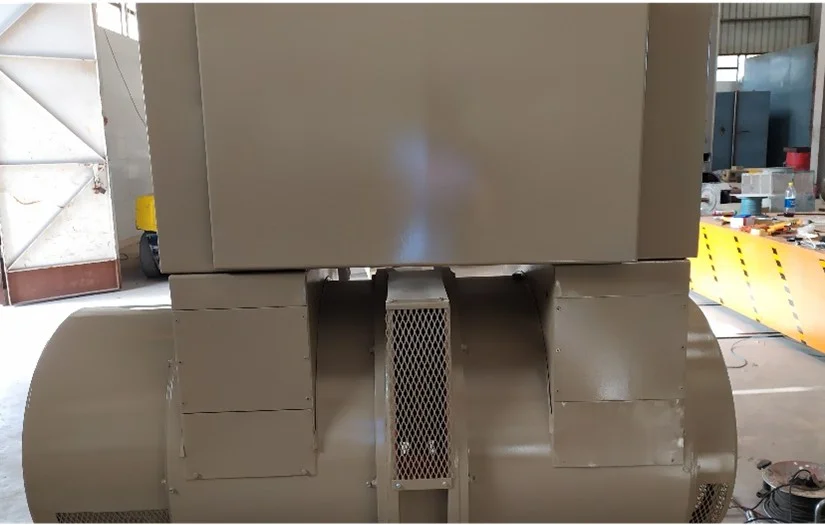

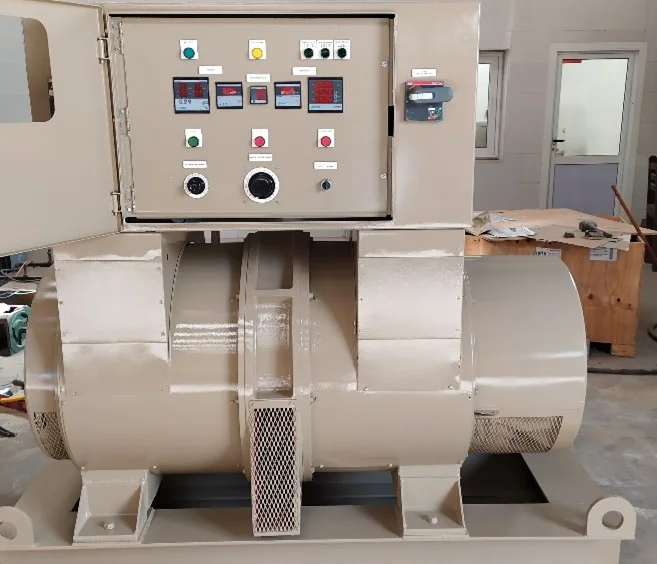

Objective: Restore and upgrade 7 KATO Motor Generators (Model 22328000) to ensure reliable 400Hz power for radar operations.

Key Interventions

- Mechanical: Bearing replacements, rotor balancing, shaft alignment

- Electrical: Stator rewinding, insulation upgrades, NEC-compliant wiring

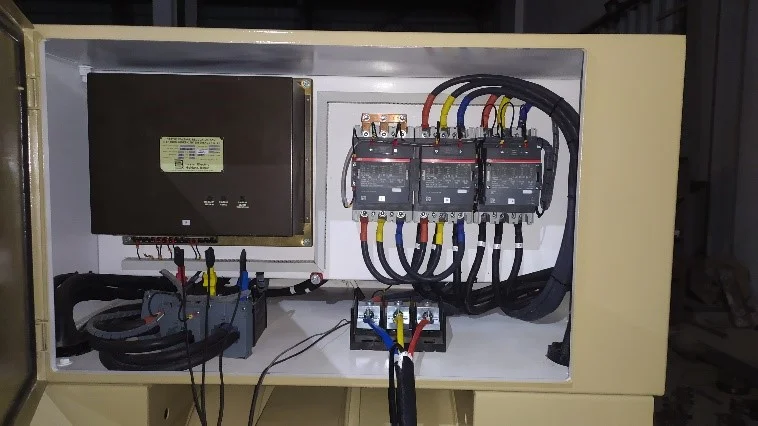

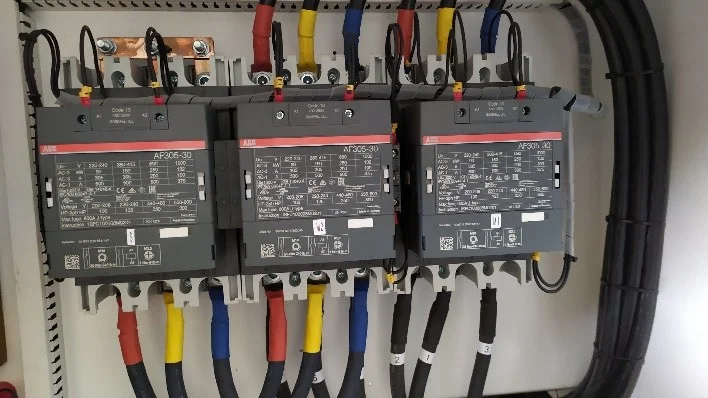

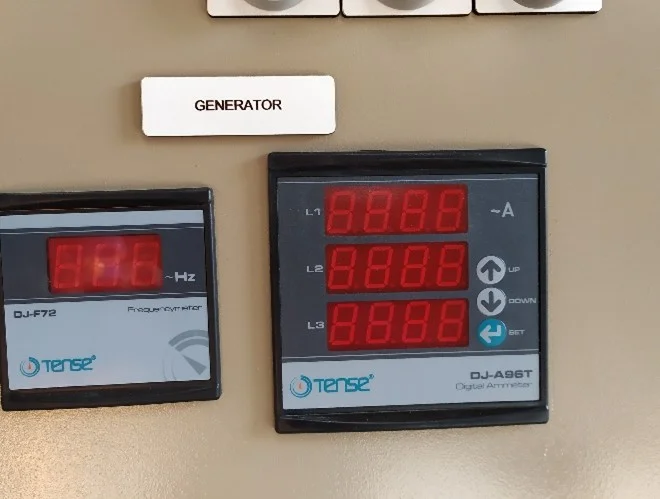

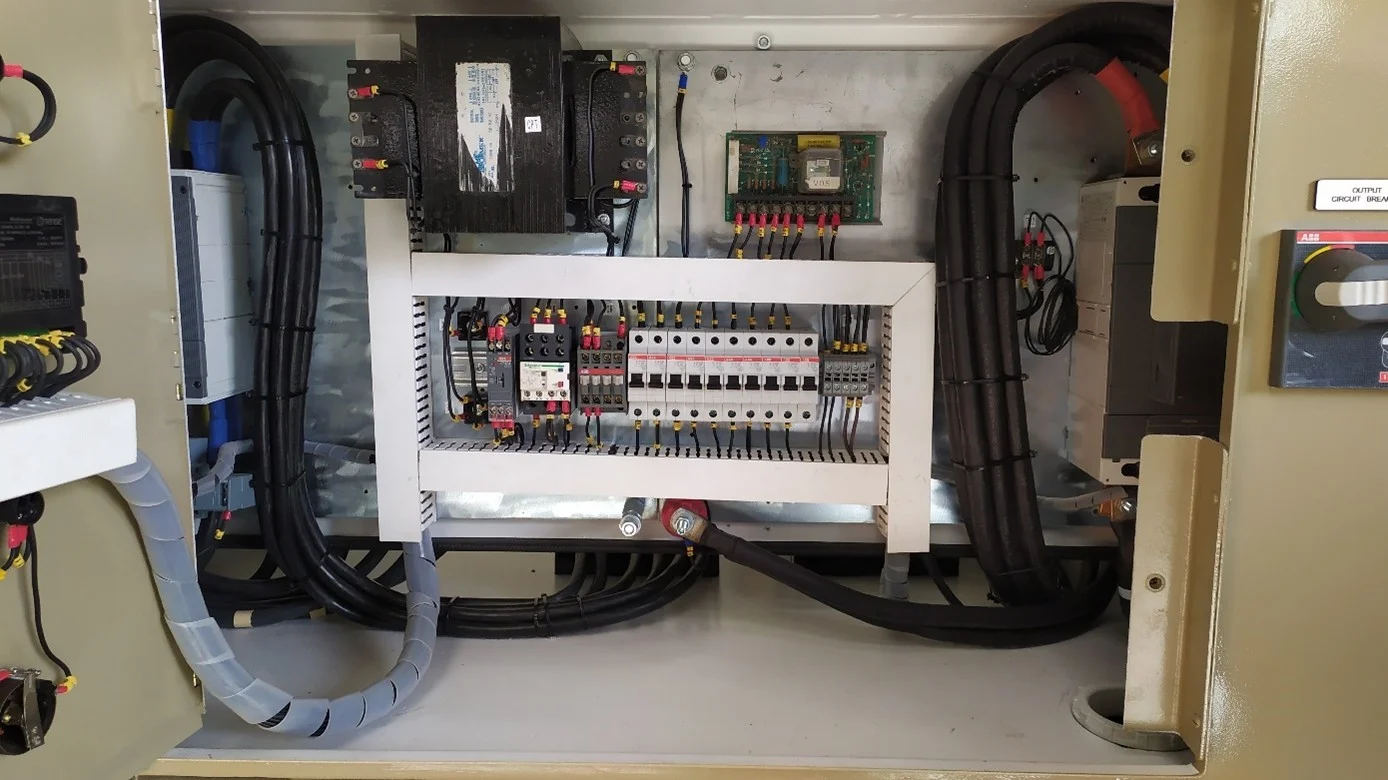

- Control Systems: Modernization of panels with digital meters, breakers, and timers

- Structural: Corrosion treatment, epoxy coatings, vibration damping

Site-Specific Repairs & Outcomes

Repair Locations & Results

| Site | Repair Focus | Outcome |

|---|---|---|

| Port Said | Complete motor overhaul | Restored 24/7 operational readiness |

| El Mansura | Exciter stator rewiring | Eliminated voltage fluctuations |

| Balteem | Rotor dynamic balancing | Reduced vibration by 40% |

| Sidi Barani | Structural reinforcement | Extended service life by 10+ years |

| Inshas | Control panel modernization | Enabled remote monitoring capabilities |

| Zaafrana | Full insulation enhancement | Achieved >7 GΩ post-repair (from 0.5 GΩ) |

| RBW 1 (Cairo) | OEM-grade bearing replacements | Noise reduction and improved efficiency |

Technical Interventions

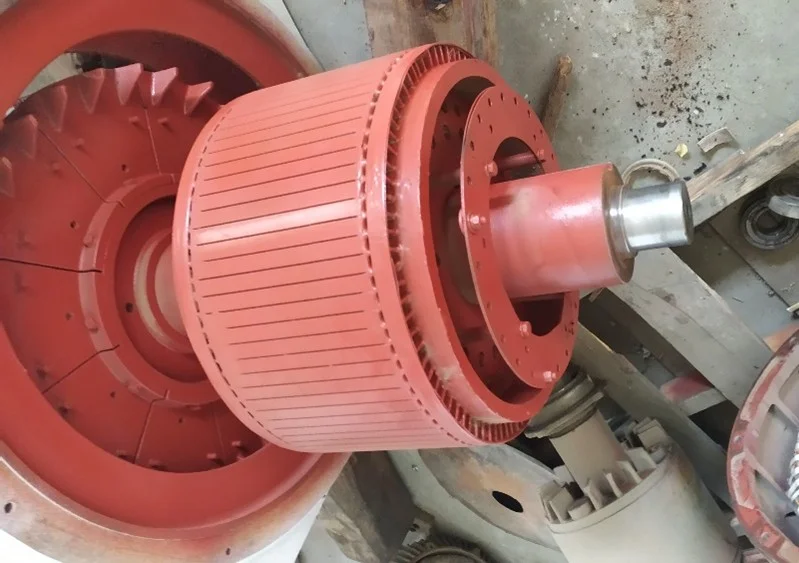

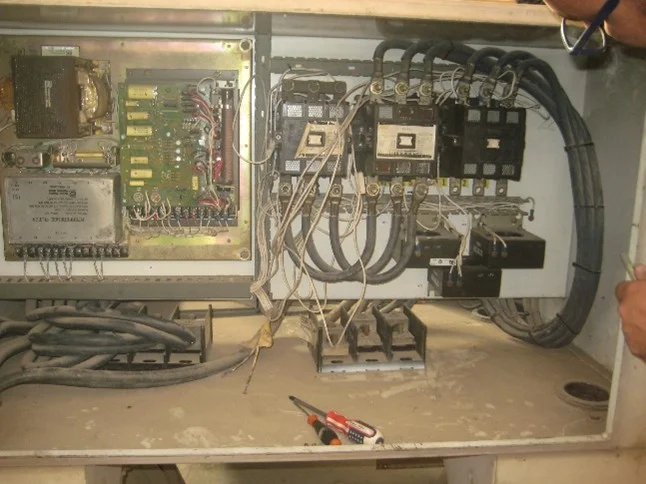

A. Mechanical Repairs

- Replaced SKF military-grade bearings in all units

- Rotor dynamic balancing (Zaafrana, Balteem)

- Shaft eccentricity checks and machining

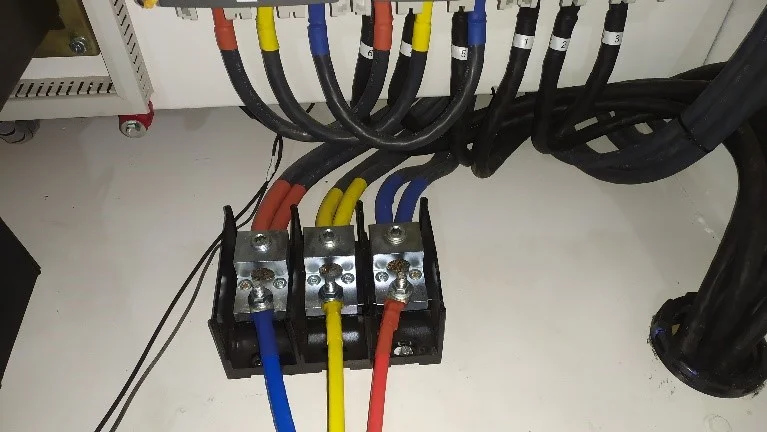

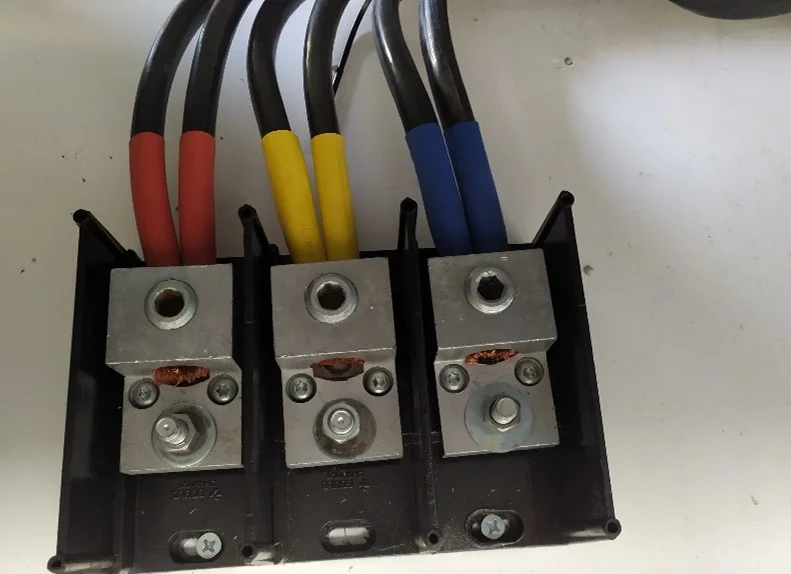

B. Electrical Upgrades

- Stator insulation enhancement (varnish, epoxy, anti-flash coating)

- Surge protector and rectifier diode replacements (Zaafrana, Inshas)

- Leakage current reduced to <10nA (from 236nA in Zaafrana)

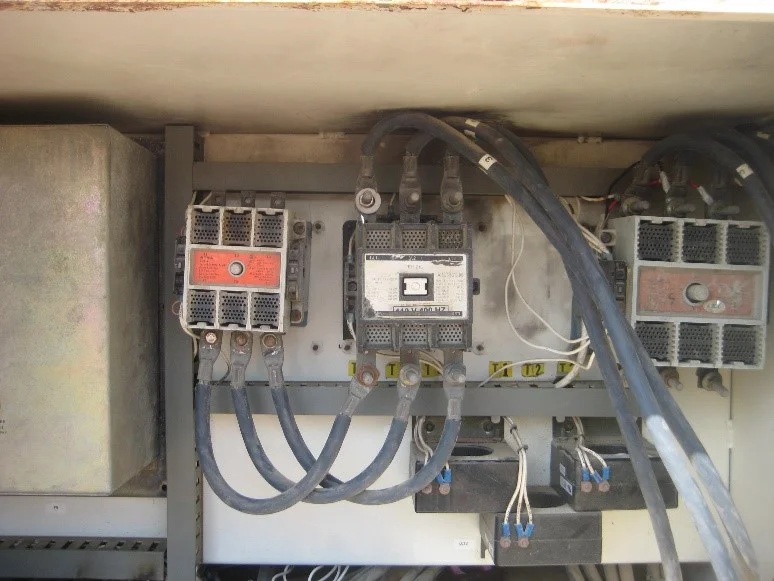

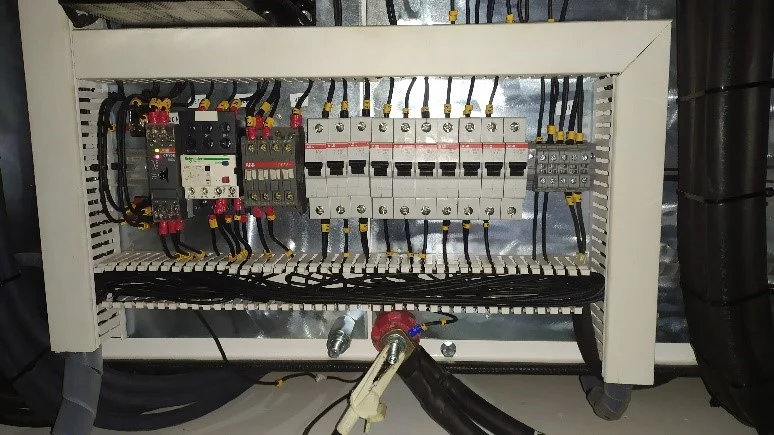

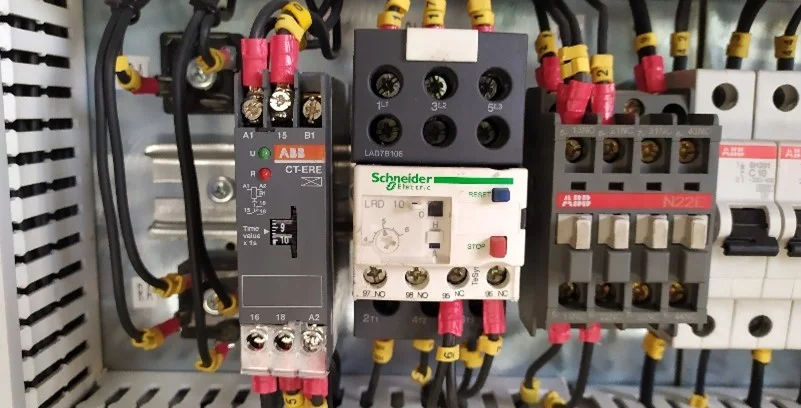

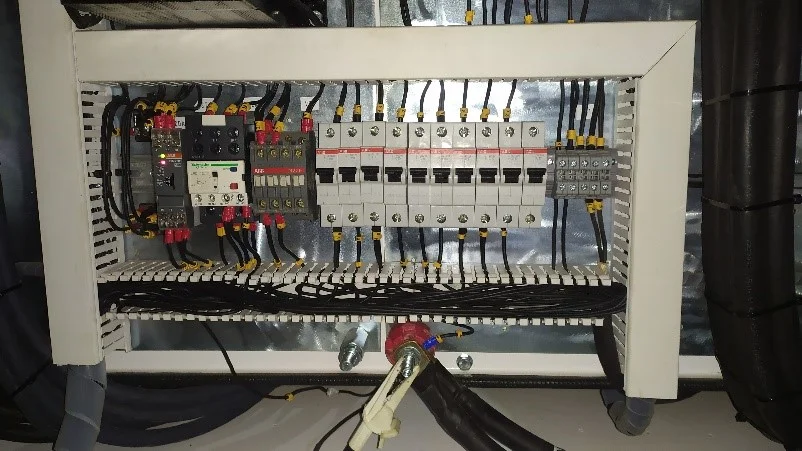

C. Control System Modernization

- Replaced analog meters with digital displays (voltage, current, frequency)

- Installed star-delta timers and 600A breakers

- New wiring with labeled conduits (NEC compliance)

D. Structural Improvements

- Corrosion-resistant painting (all units)

- Sheet metal repairs (Zaafrana, Sidi Barani)

- Vibration-dampening mounts (Port Said, RBW 1)

Execution Strategy

Phased Deployment

- Survey (2018): Thermographic, speed, and insulation tests

- Repair (2020–2021): Staggered by site (Zaafrana first, RBW 1 last)

- Testing: 72-hour load tests post-repair

OEM Collaboration: KATO-certified technicians for critical units

Documentation & Deliverables

- Per-Site Reports: Detailed documentation (e.g., Zaafrana Report Rev. 1.docx)

- Test Exhibits: RMS voltage/current graphs (input/output)

- Performance Data: Thermographic comparisons (e.g., 55.8°C → 30.7°C)

- Validation Tests: Motor speed tests (1500 RPM achieved)

Our Excellent Job