One Excellent Job Leads To Another

Workshop 60 Equipment Modernization & Refurbishment

Scope Of Work

1. Critical Systems Upgrade

New Equipment

- (2) CPS Refrigerant/Recycling Systems

- Features:

- 30% faster coolant processing

- EPA Section 608 compliance

Refurbished Equipment

- (2) RobinAir Recycling Systems

- (1) 5-ton Hyster Forklift

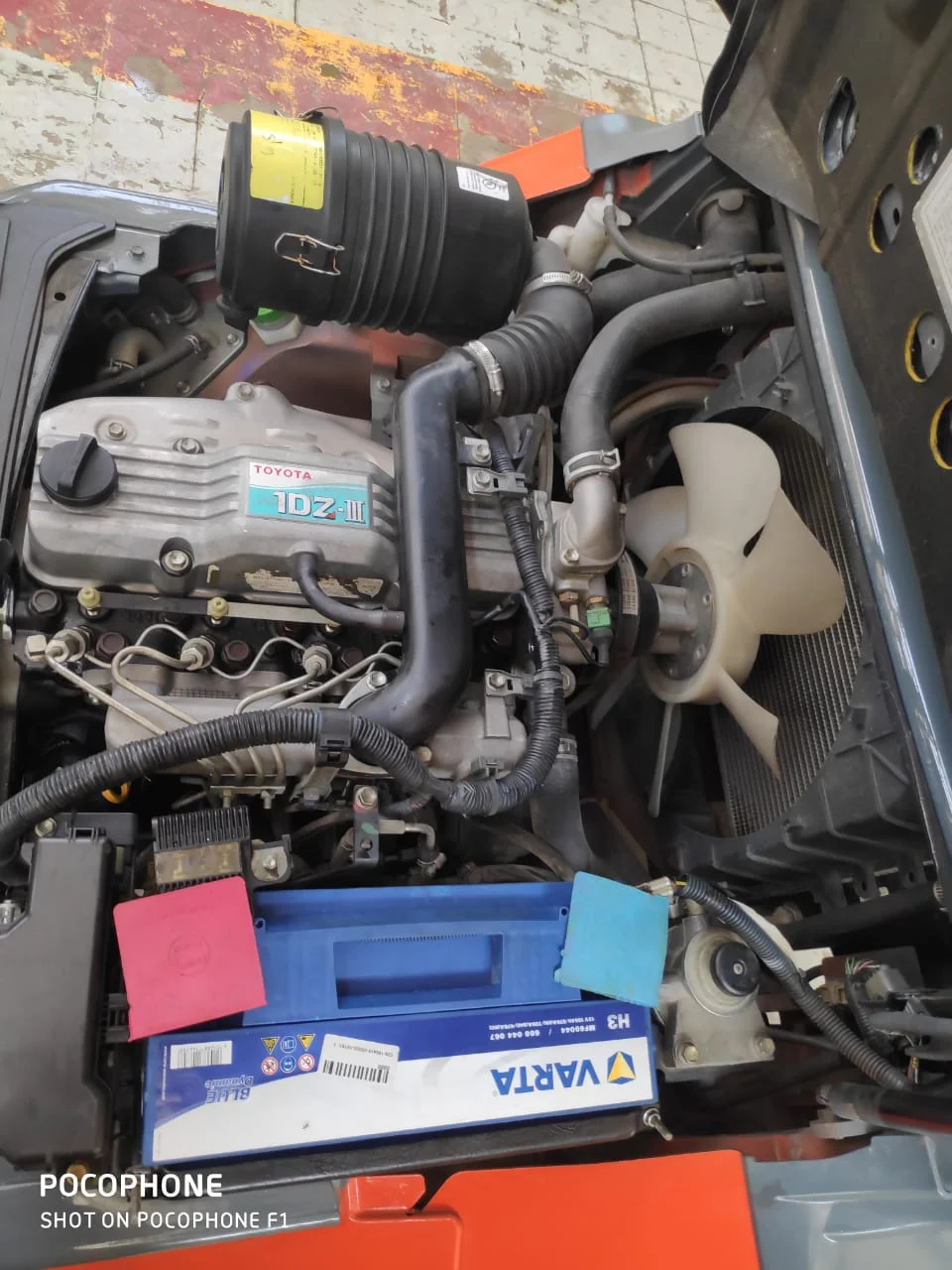

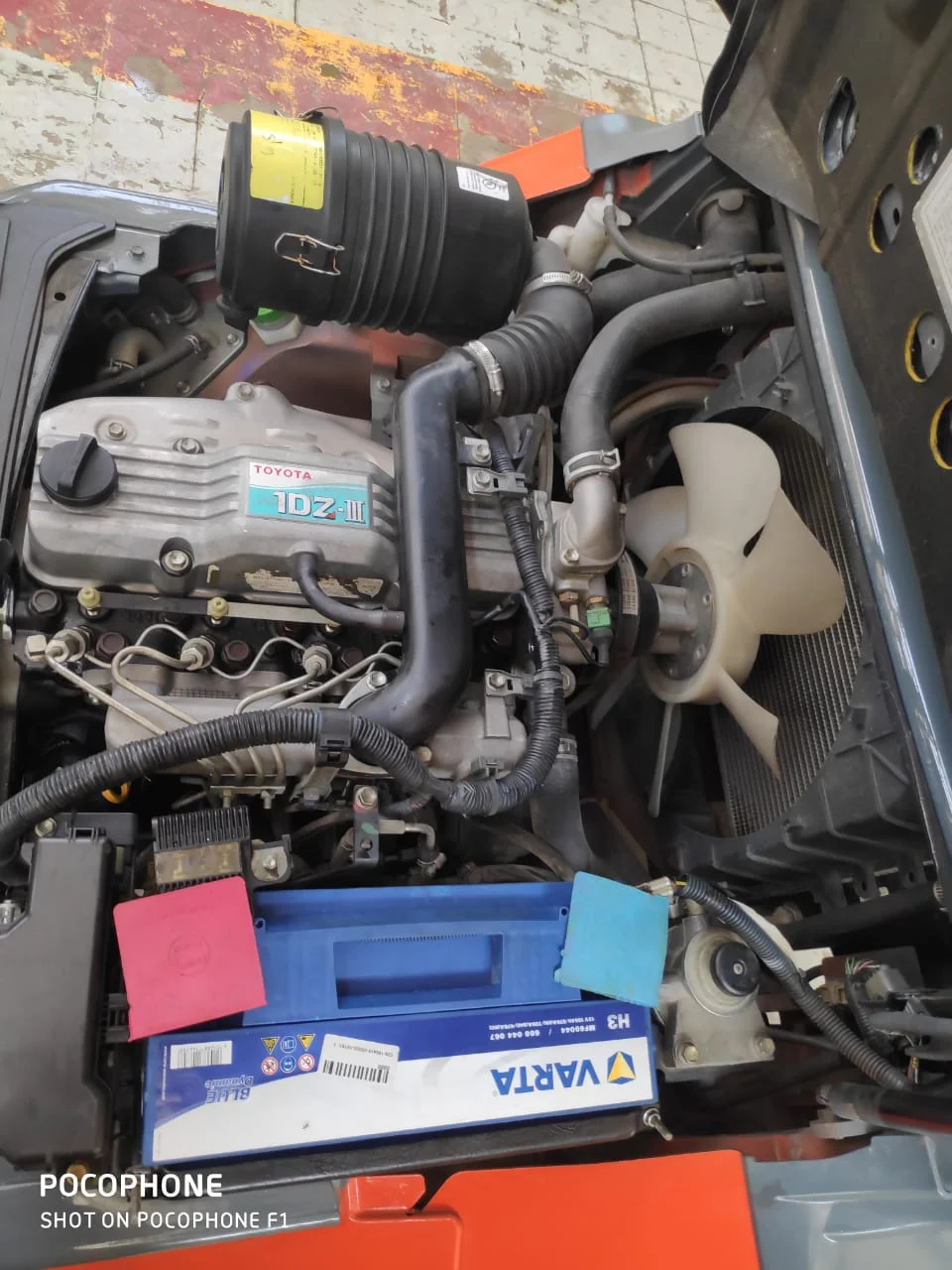

- (1) 3-ton Toyota Forklift

- Restoration included:

- Engine overhauls

- Hydraulic system rebuilds

- Safety system upgrades

Technical Specifications

Equipment Improvements & Impact

| Equipment | Key Improvements | Operational Impact |

|---|---|---|

| CPS Systems | Digital monitoring | Real-time diagnostics |

| RobinAir Units | New compressors | 50% energy reduction |

| Hyster Forklift | Reinforced mast | 8-ton lift capacity |

| Toyota Forklift | Lithium-ion conversion | 60% runtime increase |

Execution Strategy

Phased Implementation

- 1. Assessment: Full equipment diagnostics

- 2. Procurement: OEM parts sourcing

- 3. Refurbishment: Parallel team workflows

- 4. Testing: Load/performance validation

Innovations

- Custom forklift battery adapters for lithium conversion

- Retrofit kits for legacy RobinAir systems

Project Outcomes

- Cost Savings: 40% vs. new equipment purchase

- Productivity: 25% faster turnaround for vehicle maintenance

- Reliability: Zero equipment failures post-refurbishment

Our Excellent Job